Fine grain grade for rotating solid carbide tools with excellent resistance to wear and cutting edges of high mechanical resistance. For machining non-ferrous metals, aluminium alloys, composites and complex materials. This grade is particularly suitable for diamond coating.

CKi®06 is available as:

- Solid round bars, raw and ground

- Flat and square bars

- Special shapes according to drawings

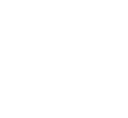

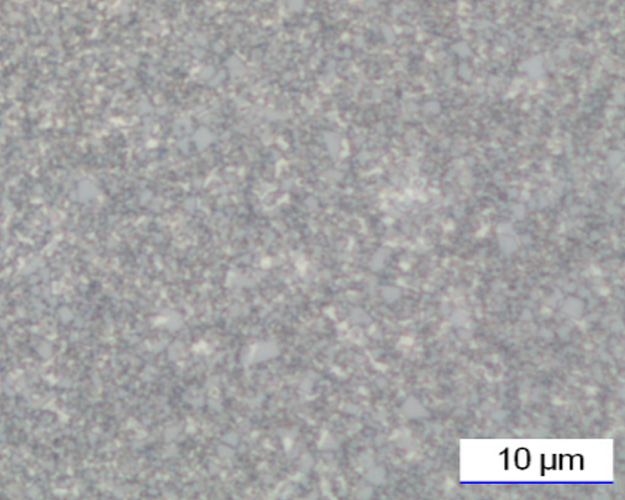

1,500x magnification of the grain structure

| ISO | K05-K10 |

| WC% | 94,0 |

| Co% | 6 |

| TiC/Ta (Nb)C % | - |

| Density [g/cm3] | 14,80 |

| Hardness [HV30] | 1900 |

| Bending strength | 3500 [N/mm2] |

| Grain size µm | 0,6 |

Universally applicable micrograin grade with high resistance to wear and cutting edges of high mechanical resistance. Suitable for rotating tools for the machining of cast iron, chilled cast iron, hardened steel, hard Al alloys, plastics with fillers, glass-fibre reinforced plastics and brake shoe linings.

CKi®08 is available as:

- Solid round bars, raw and ground

- Flat and square bars

- Fixed lengths

- Single lip cutter

- Special shapes according to drawings

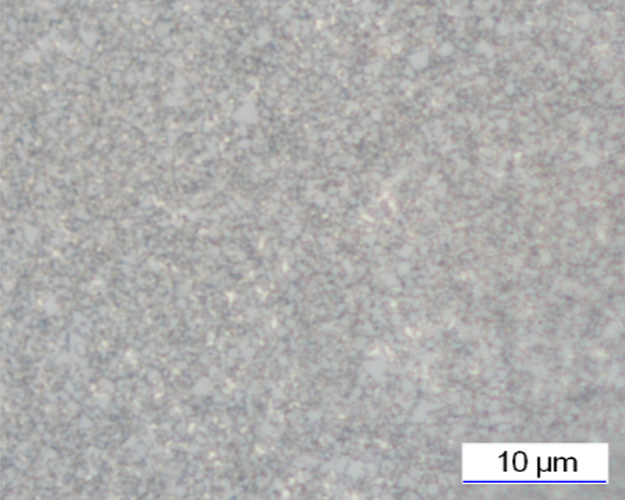

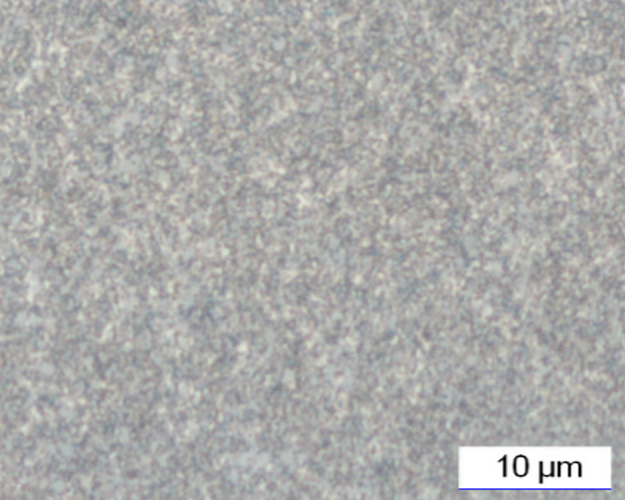

1,500x magnification of the grain structure

| ISO | K10-K20 |

| WC% | 92,0 |

| Co% | 8 |

| TiC/Ta (Nb)C % | - |

| Density [g/cm3] | 14,60 |

| Hardness [HV30] | 1710 |

| Bending strength | 3200 [N/mm2] |

| Grain size µm | 0,7 |

The high level of hardness and extreme bending strength make this carbide grade particularly suitable for boring electronics boards and other fibre-reinforced plastics as well as milling complex materials with mini-milling cutters made of CKi®09. These complex materials include titanium-carbon sandwich constructions, hardened steel, titanium alloys and stainless steels.

The extremely high wear resistance and the impressive hardness of this carbide are due to the use of super fine grained tungsten carbide powder. The specially adapted sinter-HIP process ensures a high level of toughness while also providing optimum hardness.

CKi®09 is available as:

- Solid round bars, raw and ground

- Flat and square bars

- Fixed lengths

- Single lip cutter

- Special shapes according to drawings

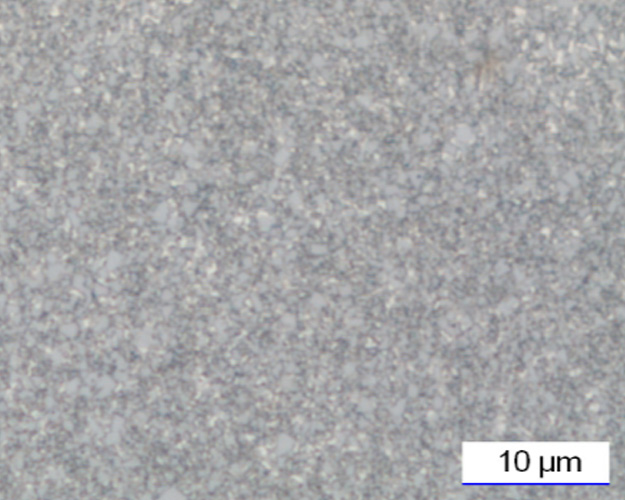

1,500x magnification of the grain structure

| ISO | K10-K30 |

| WC% | 91,0 |

| Co% | 9 |

| TiC/Ta (Nb)C % | - |

| Density [g/cm3] | 14,35 |

| Hardness [HV30] | 1930 |

| Bending strength | 3900 [N/mm2] |

| Grain size µm | <0,5 |

Ultra-micrograin grade with high toughness and hardness, thus it is particularly recommended for rotating tools for the machining of hardened parts.

Recommended for roughing and finishing with good mechanical stability of the edges and high toughness. Suitable for machining of titanium alloys, heat-resistant alloys, austenitic stainless steel grades, grey cast iron and glass-fibre reinforced plastics.

CKi®10 is available as:

- Solid round bars, raw and ground

- Flat and square bars

- Fixed lengths

- Single lip cutter

- Special shapes according to drawings

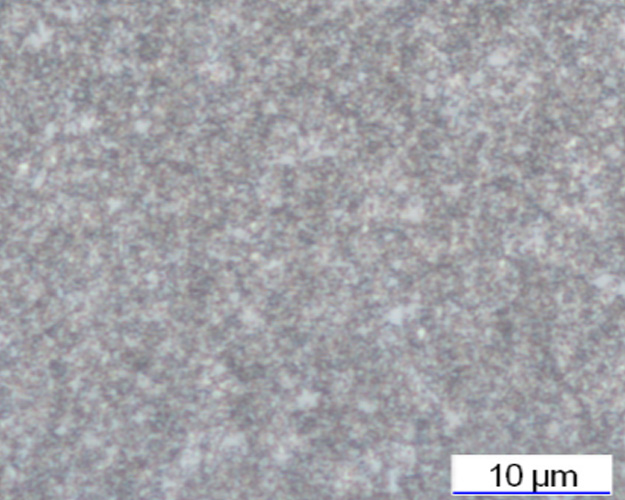

1,500x magnification of the grain structure

| ISO | K30-K40 |

| WC% | 90,0 |

| Co% | 10 |

| TiC/Ta (Nb)C % | - |

| Density [g/cm3] | 14,45 |

| Hardness [HV30] | 1610 |

| Bending strength | 3600 [N/mm2] |

| Grain size µm | 0,6 |

Ultra-micrograin grade with extreme toughness and hardness, thus highly recommended for high-speed machining of hard materials.

Very good mechanical stability of the edges under very difficult cutting conditions. Suitable for rotating tools for machining titanium alloys, heat-resistant alloys, austenitic stainless steels, hardened steels, grey cast iron and glass-fibre reinforced plastics.

CKi®12 is available as:

- We are currently stocking up – please enquire!

1,500x magnification of the grain structure

| ISO | K30-K50 |

| WC% | 88,0 |

| Co% | 12 |

| TiC/Ta (Nb)C % | - |

| Density [g/cm3] | 14,05 |

| Hardness [HV30] | 1680 |

| Bending strength | 3800 [N/mm2] |

| Grain size µm | 0,5 |