Marking

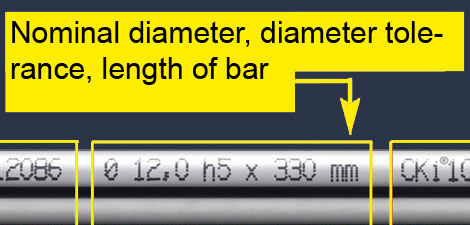

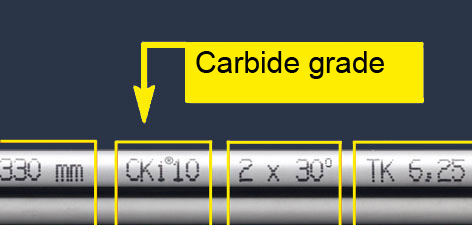

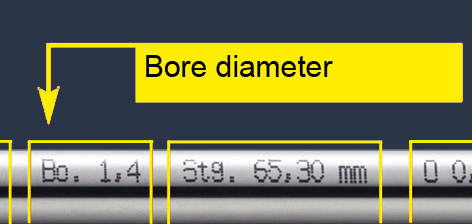

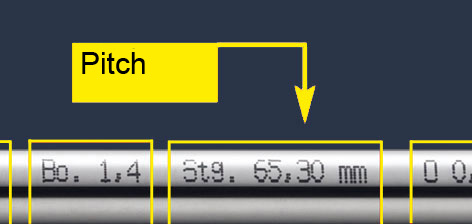

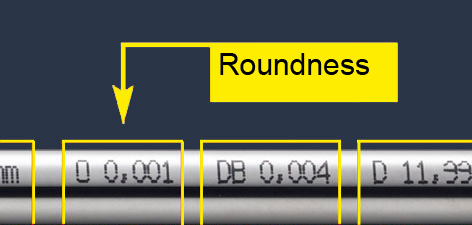

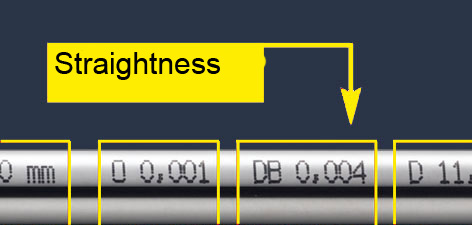

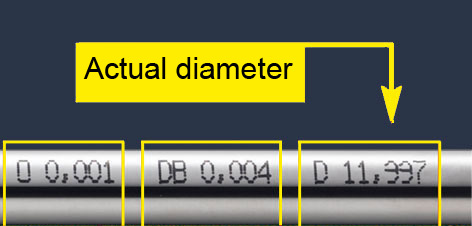

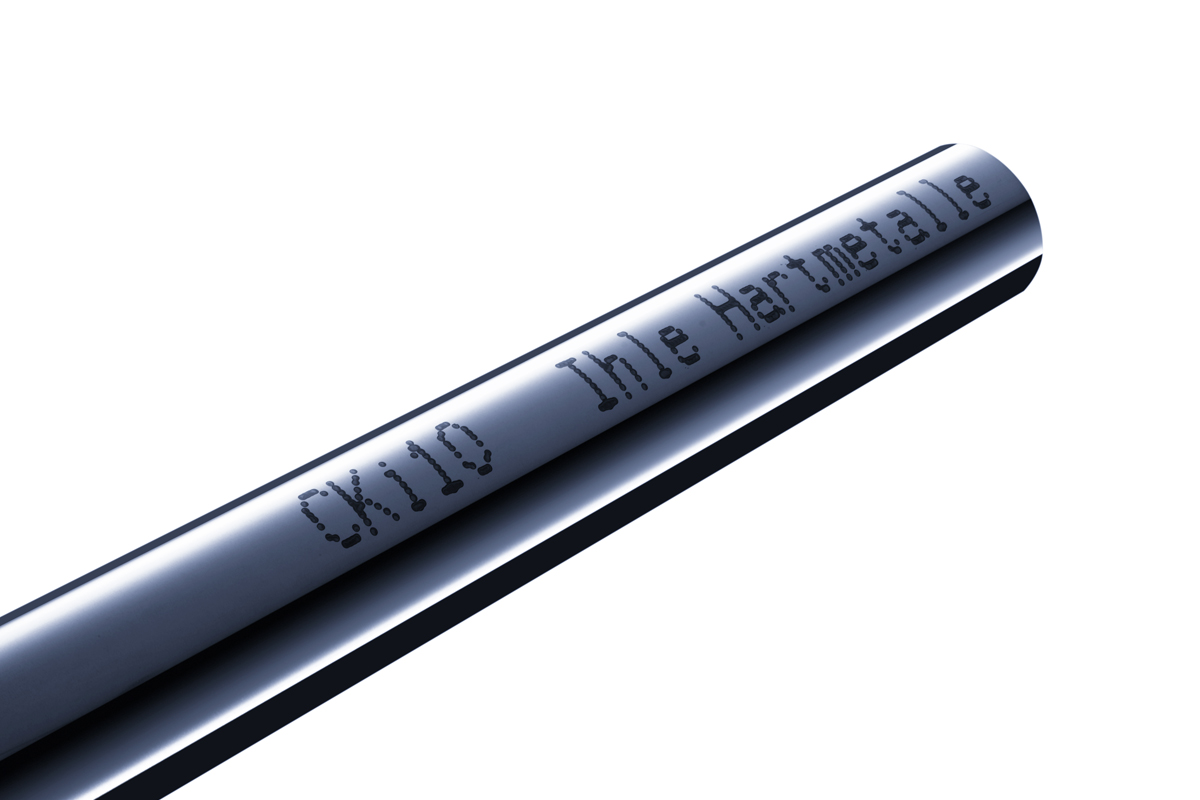

The unique nature of our range of services can also be seen in our marking. We are the only company to mark our raw bars and ground bars with a unique quality code. Thanks to our self-developed measuring and marking process, our customers can view all data that is relevant to production at a glance. Actual diameter, diameter tolerance, pitch angle, holes, length, grade and so on.

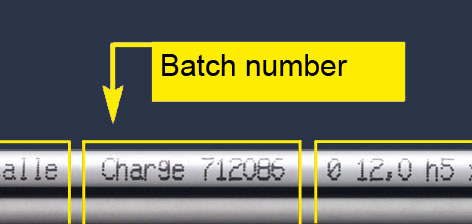

This makes it easier to ensure optimum warehousing and handling: the accompanying documents no longer need to be carried. The batch number also enables easy identification and traceability.

Not only does the innovative ink-jet printing process ensure that the marking is clearly readable, it can also be easily wiped off if required.

Batch info

Quality right from the start

The printed batch number enables the production chain to be traced at any time, thereby setting our carbide bars apart from all other suppliers. There is no risk of grade mix-ups or confusion with third-party manufacturers. Our quality is guaranteed.

In the case of raw bars and ground bars, you can see the key features at a glance: nominal diameter, diameter tolerance, bar length, carbide grade, and where applicable the number of holes and pitch angles.

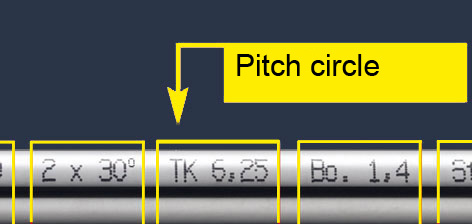

Pitch circle, hole, pitch

Optimum production reliability

Carbide bars from Ihle have all the relevant production data on them. Pitch circle, hole and pitch can be found right on the bar itself. The tedious practice of carrying accompanying documents is now a thing of the past. You save time in regard to handling and simplify your stockkeeping.

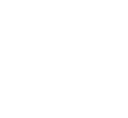

Individual measurements

The process developed by Ihle measures each bar at the same time for diameter, roundness and bending. This measuring result is then printed onto the bar individually. The result is that each bar from Ihle bears a unique quality code.

1

1 2

2 3

3