Processing methods and contract work

High quality and ready for action

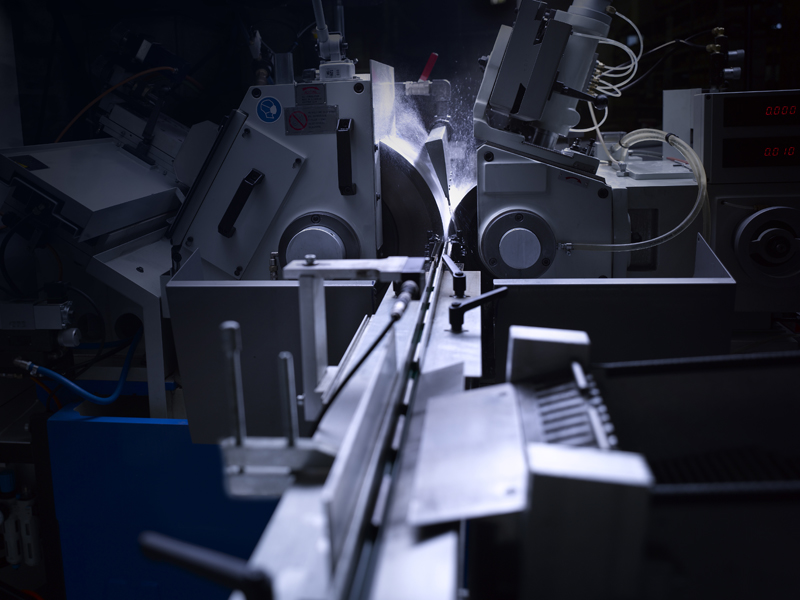

Eroding, grinding, cutting: as a specialist for all things related to carbide, we offer a comprehensive range of services in our modern machine pool. An array of processing methods which we adapt to individual requirements with full flexibility. Our main highlight is the centreless grinding, which we use to achieve high-precision tolerances: diameters between 1 and 40 mm. We offer high-precision quality with unrivalled delivery times, as it only takes a few days, or sometimes even just a few hours, for our customers to receive their order.

It’s our combination of high quality and quick availability that makes the contract work offered by us so popular. Discerning tool manufacturers know they can count on the reliable contract work by Ihle.

Carbide bars are cut to length with maximum precision on state-of-the-art machines in our cutting workshop.

Special lengths ordered in the morning normally leave the premises on the same day. This provides our customers with a great deal of flexibility and minimum storage costs.

Your advantages:

- Quick response times

- Documented quality

- Large amount of semi-finished stock

- Large amount of semi-finished stock

- Quick shipping

Benefit from our large amount of semi-finished stock and flexible grinding.

Outsourcing: we can produce clamping surfaces, cutting edges and flat bars for you. Outsource parts of your production – and rely on Ihle precision.

Your advantages:

- Quick response times

- Documented quality

- Large amount of semi-finished stock

- Large amount of semi-finished stock

- Quick shipping

Benefit from our large amount of semi-finished stock and flexible grinding.

Outsourcing: we can produce, for example, semi-finished goods for multi-station dies, drills, milling cutters, punches, shafts, nozzles, valves and constructional elements from carbide.

Your advantages:

- Quick response times

- Documented quality

- Large amount of semi-finished stock

- Large amount of semi-finished stock

- Quick shipping

We grind carbide round bars with short delivery times to achieve any diameter you need, including as contract work.

Maximum precision with regard to tolerance, roundness and run-out guarantees optimum results for the final product. Many intermediate sizes and tolerances (inch dimensions h5, h6, h7, etc.) are available from stock.

Your advantages:

- Quick response times

- Documented quality

- Large amount of semi-finished stock

- Large amount of semi-finished stock

- Quick shipping

On our CNC-controlled die sinking machines we erode through or coolant holes, as well as threads in carbide.

Our many years of experience enable us to also carry out erosion of complex geometries as well as normal spark eroding. We erode holes up to a depth of 300 mm while carefully handling the carbide.

Your advantages:

- Quick response times

- Documented quality

- Large amount of semi-finished stock

- Large amount of semi-finished stock

- Quick shipping

Perfectly protected

Here at Gerhard Ihle Hartmetalle Werkzeuge e.K. we do everything we can to provide our customers with the best results. Quality is always foremost in our minds not only when it comes to the raw material but also for all subsequent work steps. So it makes sense for us to also offer solutions for safe transport. Thanks to our clever packaging range, high quality carbide tools reach customers’ production facilities safe and sound.

Multi packaging with multi-chamber system featuring detachable individual chambers

No need to change packaging or even repack individual pieces – thanks to the hinge lock, the individual chambers are reclosable.

Protective lid to protect tool cutting edges

The protective lids made from flexible PE are easy to attach and remove again and protect sensitive tool cutting edges. What is more, they prevent tool tips from being coated during surface treatment.

Protective packaging with twist cap

The round protective and packaging sleeves with rotary length adjustment mechanism and rollaway protection can be re-closed and reused several times, plus they are robust, and moisture and oil resistant.

Set box with PE foam inserts

Our set and assortment boxes provide optimum protection for cutting tools and can be supplied with various PE foam inserts for different diameters.